In the ever-changing business landscape entrepreneurs need to be modern, progressive, move with the times and first of all, they should be ready to meet the challenges of the modern world. One of such challenges constitutes environmental aspects and understanding the negative aspects of man’s activity that translate into environmental pollution, running out of natural resources, or climate changes. A modern enterprise needs to be managed in a strategic and market way and promote innovative solutions. This also includes the environmental impact evaluation. Thus, contemporary eco-innovative actions are perceived as a vital element of environmental policy and they are indispensable to comply with the requirements of environmental protection and at the same time build economic competitiveness. Implementing eco-innovations improves the efficiency of enterprise operations. It allows decreasing the cost of operations through reduced consumption of energy, water, and other materials improving simultaneously effectiveness and profitability of operations. This helps to meet the requirements of ever-stricter legal regulations pertaining to environmental protection and using environmentally-friendly processes is more frequently notices or even appreciated by customers. This is also the case with Uniflora, an enterprise that not only strives to be a responsible leader in its business, but also wants to be perceived as a company that takes care of its employees, customers, and the environment.

Uniflora Sp. z o.o. is a company with many years of tradition operating in the business of safety food. Within the last few years, the company has become a leader in its business. It provides selected products of guaranteed quality. The basic assortment of products includes lettuces, herbs, micro-leaves, and vegetable sprouts. The products are grown exclusively with the use of light, water, and temperature, from examined seeds that come from selected suppliers. The product does not require pre-treatment and are ready for consumption. In 2012 Uniflora implemented the international Food Safety Standard. In 2014 the company obtained the BRC certificate – Global Standard for Food Safety and in 2017 after it commenced the hall with the most modern technology for producing Mung beans it became the leader in the production of this type of sprouts in Europe.

Initially, the operations of Uniflora in the scope of creating and implementing innovative solutions, eco-innovative ones in particular, were quite limited. The perception of innovative solutions as a driver of the company’s development was at a very high level from the very beginning, yet financial capabilities and access to expert knowledge were limited. Therefore, being fully aware of the need to implement innovative solutions being an impulse for the company’s further development, it began a collaboration with Czestochowa University of Technology, Department of Advances Energy Technologies. The collaboration with the abovementioned R&D unit allowed Uniflora to gain access to R&D facilities and expert knowledge in the scope of technologies of utilizing off heat and energy transformations. It needs to be stressed that competencies of the employees of Czestochowa University of Technology in the scope of knowledge and experience in recognizing the possibilities of acquiring financing for innovative undertakings from various external sources contributed to carrying out two innovative projects.

The first carried out the project was POIR.01.01.01-00-0759/17 „Comprehensive energy-saving pilot line for production of vegetable sprouts of improved qualitative parameters”. Its goal was to develop and implement the technology for producing Mung beans sprouts of the determined by customers qualitative parameters and prolonged transport durability, at the same time reducing the consumption of primary fuels. Thanks to the collaboration between the two units a pilot line was developed and implemented, which complied with the assumed requirements. An interesting, eco-innovative idea was the application of internal heat retrieval from biological processes and the implementation of renewable energy sources. This allowed to limit the consumption of primary fuels almost completely and the demand for water was significantly decreased. The implemented technological line is practically a zero-emission one and the produced Mung beans sprouts are a fully ecological product.

The positive experiences from the collaboration within the first project led to the acquisition and implementation of another project POIR.01.01.01-00-0058/19 „ A pilot line for production of sunflower sprouts of improved qualitative parameters”, for which external financing was also acquired. Presently, the project is being implemented and its end is planned in 2022. A measurable result of the collaboration between the R&D unit – Czestochowa University of Technology and Uniflora, a representative of the sector of small and medium-sized enterprises will be developing the technology of growing the sunflower sprouts of improved qualitative parameters, satisfying the expectations of customers, making use of energy-saving technology of LED light sources.

Eco-innovations as a vital element of SMEs activity

In the constantly changing business landscape we all need to be modern, progressive, accept new trends, move with the times, and above all meet the challenges of the contemporary world. One of such challenges are environmental issues and understanding the negative effects of development, which translate into pollution of the environment, exhaustion of resources or climate changes. Thus, a modern enterprise needs to be managed in a strategic, market and eco-innovative manner. Contemporary eco-innovations are perceived as a vital element of pro-environmental policy, are indispensable to comply with the requirements of environmental protection and simultaneously build economic competitiveness. Application of eco-innovations improves the results of SMEs activity as it allows for a decrease in the cost of operation through reduced consumption of electricity, water and materials simultaneously improving the efficiency and profitability of actions. It also helps to adjust to ever stricter legal requirements pertaining to environmental protection.

The ECOLABNET network

Nowadays, acquisition of reliable knowledge about eco-innovations is harder than ever before. Therefore, a need exists to provide data on eco-innovative products and services so as to put in touch creators of such solutions with potential recipients. The ECOLABNET network is simply an answer to the lack of professional network for providing counselling services in the scope of eco-products for small and medium-sized enterprises in the Baltic Sea Region. It offers broader access to expert knowledge, new products and services as well as supports competitiveness on the side of small and medium-sized enterprises. ECOLABNET increases the commercialisation potential of various eco-innovations coming from R&D institutions.

Time for the Digital Collaboration Tool

Digital Collaboration Tool (DCT) within the ECOLABNET project is a digital places where R&D units, intermediary organisations and above all small and medium-sized enterprises can meet, regardless of the fact whether they seek for new possibilities or simply maintain good relations with present co-operators working in a given subject scope of eco-innovations. Therefore, the DCT allows to reach proper entities that consider a pro-environmental attitude in their operations, manufacture new products, offer interesting services, and create pro-environmental technologies. This is a wide range of entities as environmental protection covers a number of domains of science and economy and the demand for eco-innovative solutions is growing.

So, if you want to:

- be up-to-date with latest solutions in the scope of eco-innovations,

- learn about eco-innovative solutions that bring measurable effects,

- find new, potential partners or customers,

- get in touch with new customers,

- more effectively involve customers

the developed within the ECOLABNET project digital place of cooperation is just for you.

The DCT is currently being developed. We expect it to be ready in Q2 of 2021.

Praca zdalna ma także swoje zalety aczkolwiek brak nam już bezpośredniego kontaktu i spotkań.

written by Rathish Rajan from Centria UAS, Finland

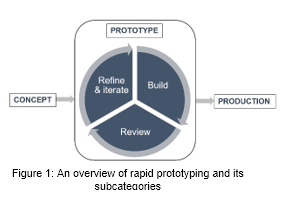

Today, prototyping is a crucial part of the industrial product development process to remain competitive in the business. A prototype is a physical representation of a whole product or a component of a product that, although limited in some aspects, can be used for testing, design, and evaluation. Prototypes must be quickly and simply producible, easy and safe to recycle and as an impermanent object of product development, it should be economical.

Rapid prototyping, as the name implicates, is referred to different techniques used to quickly and economically produce a model of a product or part of an assembly by using additive manufacturing (Figure 1).

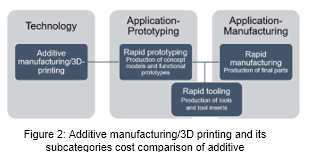

Since the 1990’s the term rapid prototyping is associated with additive manufacturing technique. Today rapid prototyping is described as a subset of additive manufacturing that deals with the production of prototypes (Figure 2) (Gebhardt & Hötter, 2016).

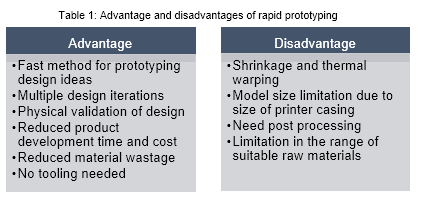

Additive manufacturing or most commonly named as 3D printing is an additive process of depositing material layer by layer to produce a 3D model of the product or component of an assembly. The traditional manufacturing techniques like injection molding and CNC need expensive tooling and setup, which makes low-volume production of prototypes highly expensive. Rapid prototyping has numerous benefits, but like many other technologies, it too has some disadvantages (Table 1).

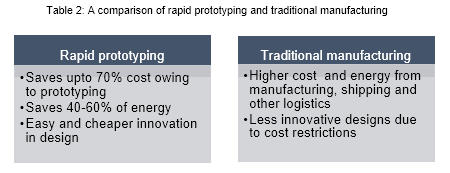

One of the biggest advantages of rapid prototyping over traditional manufacturing methods is that rapid prototyping does not require any special tooling to make the model. For the same reason, the rapid prototyping method is benefited compared to the traditional method in terms of time, energy, money, and material saved (Table 2) (Rathi, 2018). Rapid prototyping has its limitation in the maximum achievable size of the model and lacks the features like creating many moving parts that interlocks and work together like in traditional methods.

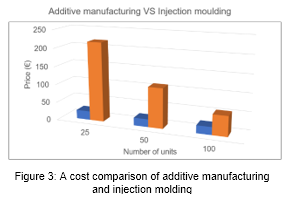

Based on few case studies, Sculpteo, a French rapid prototyping service provider (Sculpteo, 2014), concluded that additive manufacturing compared to injection molding is economically beneficial when considering the production of parts below 500 units (depending on size) and for producing complex objects. Figure 3 represents the data adapted from Sculpteo case study for a car handle (Sculpteo, 2014).

This shows that rapid prototyping is economically beneficial over traditional manufacturing when low volume production like prototyping is considered. However, to produce very large prototypes, traditional prototyping methods are economically suitable than rapid prototyping.

References

Gebhardt, A., & Hötter, J. (2016). 4 - rapid prototyping. In A. Gebhardt, & J. Hötter (Eds.), Additive manufacturing (pp. 291-352) Hanser. Retrieved from http://www.sciencedirect.com/science/article/pii/B9781569905821500058

Rathi, C. (2018, -01-12T08:21:24+00:00). Traditional manufacturing vs 3d printing – A cost analysis. Retrieved from https://precious3d.com/traditional-manufacturing-vs-3d-printing/

Sculpteo. (2014). 3D printing or injection molding: Guide to cost efficiency. Retrieved from https://www.sculpteo.com/en/ebooks/3d-printing-vs-injection-molding/

SPOTKANIE ROBOCZE - 27-29.11.2019 - POLITECHNIKA CZĘSTOCHOWSKA

W dniach 27 – 29 listopada 2019 roku w Częstochowie miało miejsce drugie spotkanie robocze partnerów projektu ECOLABNET Network of Service Providers for Eco-innovations in Manufacturing SMEs, realizowanego w ramach programu Interreg Region Morza Bałtyckiego,którego celem jest stworzenie sieci usługodawców wspierających innowacje ekologiczne w produkcji MŚP z regionu Morza Bałtyckiego. Spotkanie zostało zorganizowane przez partnera projektu Politechnikę Częstochowską.

W spotkaniu uczestniczyli przedstawiciele następujących partnerów projektu:

- VAMK Ltd, University of Applied Sciences, Design Centre MUOVA, Finlandia

- Kaunas University of Technology, Litwa University of Tartu, Estonia

- Czestochowa University of Technology, Polska

- VIA University College, Dania

- Vilnius University, Litwa

- Lithuanian Business Confederation, Litwa

- Sustainable Innovation, Szwecja

- Centria University of Applied Sciences Ltd, Finlandia

- Labsamera MB, Litwa

- Estrotech Ltd, Estonia.

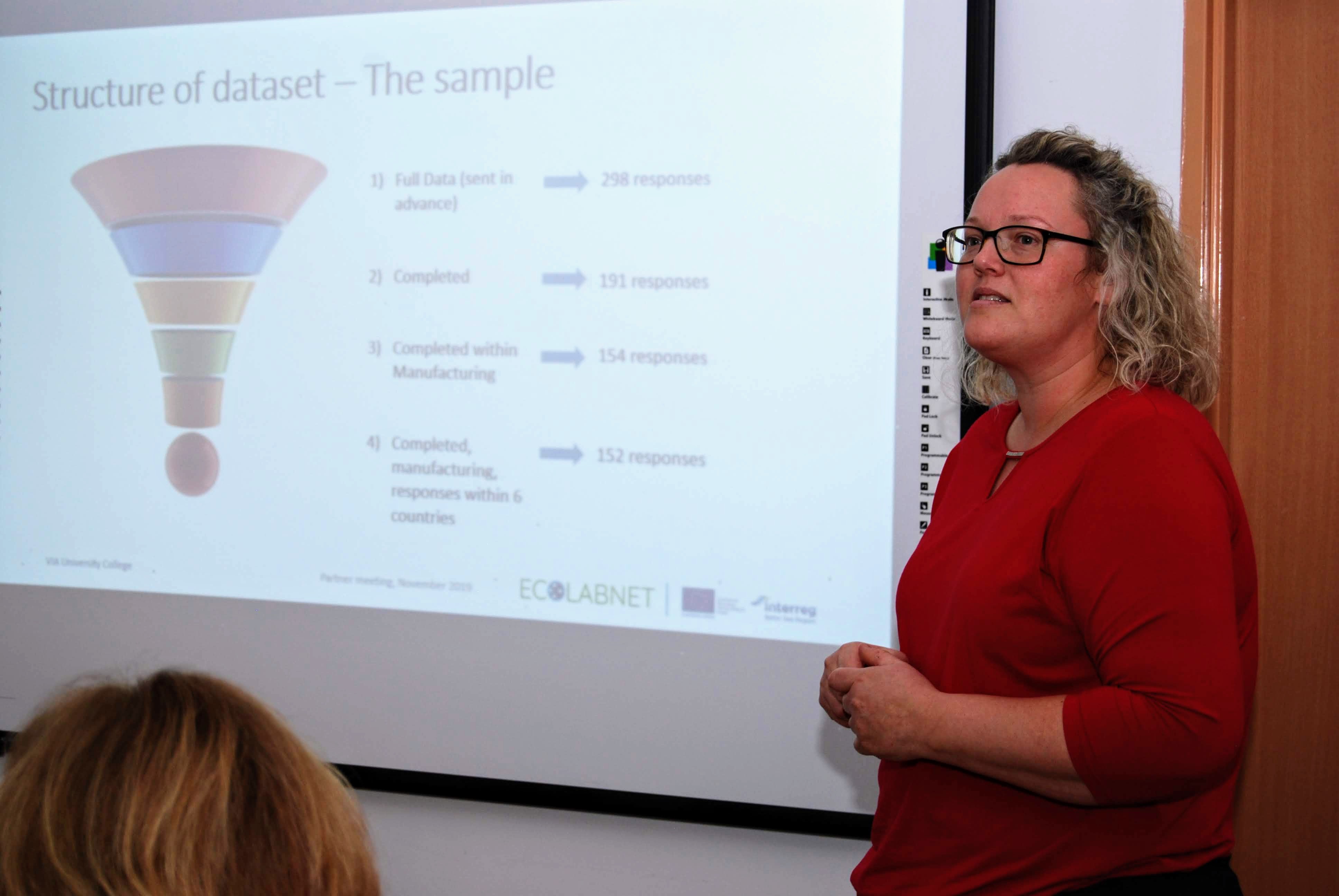

W pierwszym dniu spotkania, zorganizowanego na Wydziale Infrastruktury Środowiska Politechniki Częstochowskiej, partner PCz przedstawił uczestnikom spotkania kompetencje zespołu roboczego oraz zaprezentował wyposażenie laboratoriów oraz infrastrukturę uczelni. Koordynator projektu (MUOVA) scharakteryzował aktualny stan realizacji projektu. Odbyła się także sesja warsztatowa, w ramach, której omówiono wyniki badań ankietowych przeprowadzonych wśród MŚP i organizacji pośredniczących (VIA & LBC). Drugiego dnia, uczestnicy spotkania gościli na Wydziale Zarządzania Politechniki Częstochowskiej, w ramach którego odbyły się kolejne sesje warsztatowe.

|  |  |

Pierwszy warsztat prowadzony przez MUOVA, dotyczył dalszej analizy wyników badań ankietowych w kontekście profili respondentów MŚP oraz organizacji pośredniczących. Drugi warsztat obejmował prezentację narzędzi do mapowania, laboratoria, sieci dla ECOLABNET (UTartu). W trakcie warsztatu prowadzonego przez Centria i VU, członkowie zespołów projektowych brali również czynny udział w prezentacji pomysłów na prototypy, gdzie następnie dokonano wyboru pięciu najlepszych. Kolejne dwa warsztaty dotyczyły omówienia i charakterystyki cyfrowych narzędzi współpracy (CUT) oraz modelu współpracy zewnętrznej (VIA), w trakcie których wymieniono wiele ciekawych spostrzeżeń i zebrano wiele cennych pomysłów na dalsze etapy realizacji projektu.

|  |  |

Po części merytorycznej, uczestnicy spotkania udali się z przewodnikiem do Sanktuarium na Jasnej Górze, gdzie mogli podziwiać zabytki Klasztoru Ojców Paulinów, a wśród nich imponujący zbiór ksiąg, z których najstarsze pochodzą z XV wieku. Wieczorem miała miejsce uroczysta kolacja, w ramach której uczestnicy wymieniali się spostrzeżeniami i uwagami ze spotkań warsztatowych. Ponadto aktywnie dyskutowano na temat dotychczas podjętych działań oraz ustalano terminarz przyszłych spotkań projektowych.

|  |  |

Ostatni dzień, bardzo owocnego spotkania uczestnicy spędzili w siedzibie firmy ELQ S.A. Po przedstawieniu profilu działalności firmy odbył się warsztat na temat strategii i rozwoju sieci ECOLABNET, prowadzony przez zespół LBC. Po warsztacie koordynator projektu MUOVA dokonał podsumowania spotkania i omówił kolejne kroki na którymi powinni się skoncentrować zespoły projektowe, m.in. przygotowanie raportu rocznego. Po zakończeniu podsumowania prezes firmy ELQ S.A. Marcin Sołtysiak zaprosił uczestników spotkania do udziału w wizycie studyjnej na hali produkcyjnej firmy. Była to dobra okazja do poznania tajników produkcji stacji transformatorowych, projektowania i budowy farm fotowoltaicznych oraz stacji ładowania pojazdów elektrycznych.

Po wspólnym lunchu, uczestnicy wyruszyli w podróż powrotną, z nadzieją na ponowne spotkanie na Litwie, gdzie już w kwietniu 2020 roku, odbędzie się kolejne spotkanie robocze zespołów projektowych ECOLABNET.

Strona 1 z 2

- start

- Poprzedni artykuł

- 1

- 2

- Następny artykuł

- koniec